MIX CONCRETE WHENEVER AND WHEREVER

MIX CONCRETE WHENEVER AND WHEREVER

| Aggregate bin | 2 bins or 3 bins or 4 bins |

| Aggregate bin measurement method | Individual metering or cumulative metering |

| Incline belt conveyor width | 800mm or 1000mm |

| Water weighing | Turbine flowmeter |

| Additive weighing | Turbine flowmeter |

| Measuring accuracy | ±2% |

| Control system | Siemens PLC, touch screen, Schneider Electric Components |

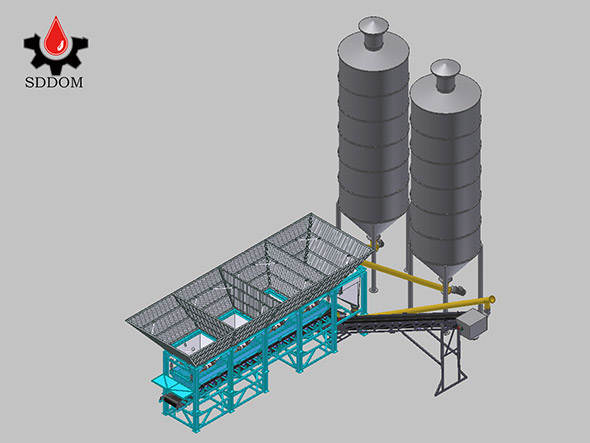

The dry mixing plant consists of four essential systems, including storage system, weighing system, conveyor system and control system.Main Parts of dry Mixing Plant:

Storage system includes batching machine, cement silos. PL series batch machine allows for automatic batching equipment, equipped with electronic weighing and digital display. Powder, are respectively stored by cement silos. Cement silos can store such powder as cement, ash and coal, which are components of concrete.

Features of Storage System:

1.High accuracy, high speed, powerful control function and easy operation are the batching machine signature traits;

2.The batching machine for the plant can be manufactured into 2 bins, 3 bins and 4 bins in accordance with your demands.

The weighing system includes aggregate weighing, cement weighing, water weighing and additive dosing weighing. And weighing by means of weighing hopper, weighing sensor and batching controller.

Features of Weighing System:

Accurate weighing. The dry mixing plant adopts the method of accumulative measurement and automatic system, thus it performs accurate when weighing.

Conveyor system is produced to convey aggregates, powder, water and liquid from storage bins to weighing hopper. Aggregate is conveyed by a hopper, and the powder and liquid are separately by screw conveyor and pump.

Features of Conveyor System:

1.Long servicing life;

2.Supply spare parts for free;

3.Obtain products certificates of ISO9001 and SGS Test.

PLC control system is used to inspect and control concrete discharge area, batching condition, and weighing condition.The control system includes computer, power supply cabinet, control cabinet and field monitoring control, making the batching accuracy within 2 percent. The control system employs the components of Simens. Depending on requirements of customers, we have manufactured such two control system as the semi-automatic and automatic control.

Features of PLC Control System:

1.Accurate. The whole operation is controlled by automatic system, thus it performances more accuracy;

2.Easy operation. Equipped with automatic control, batching and weighing system, our dry mixing plant is easy to operate.

Successful Case of fixed dry mixing plant(customized):

Sddom One Stop Solution:

Sddom After-sales Service:

Oversea warehouses are established in Philippines, Uzbekistan, Pakistan, Indonesia, Malaysia and so on. Thus, if there is any problem, you can contact us immediately, and the plant will be maintained quickly in low cost.